Credit, Kromek

-

- author, Chris Baraniuk

- To roll, BBC Technology Journalist

-

Reading time: 5 minutes

Lying on your back inside a large scanner, as still as possible, with your arms above your head for 45 minutes is not the most fun.

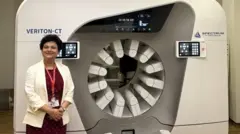

This is what patients at the Royal Brompton Hospital in London had to do during certain lung examinations. But with the installation of new equipment last year, the time was reduced to just 15 minutes.

This is due in part to the device’s image processing technology, but also to a special material called CZT (an acronym for cadmium zinc telluride), which allows the machine to produce highly detailed three-dimensional images of patients’ lungs.

“With this scanner, we get wonderful images,” explains Dr. Kshama Wechalekar, head of the nuclear medicine and PET (positron emission tomography) department at the hospital.

“It’s a true feat of engineering and physics.”

The machine’s CZT was manufactured by the British company Kromek, one of the few in the world that can produce it.

You may have never heard of him, but — in Wechalekar’s words — he’s sparking a “revolution” in medical imaging.

This incredible material still has many other uses, such as in x-ray telescopes, radiation detectors, and airport security scanners.

And its demand is only growing.

Credit, Guy and St Thomas NHS Foundation Trust

The research Wechalekar and colleagues are doing on patients’ lungs involves detecting many small blood clots in people with long Covid, or one larger clot called a pulmonary embolism, for example.

The scanner, which costs £1 million (around 7.4 million reais), works by detecting gamma rays emitted by a radioactive substance injected into patients’ bodies.

But the sensitivity of the scanner also means that a smaller amount of this substance is needed than before.

“We can reduce the doses by around 30%,” specifies the doctor.

Big demand, little supply

Although CZT-based scanners are not new, large body pieces like this are a relatively recent innovation.

CZT has been around for decades, but it is notoriously difficult to manufacture.

“It took a long time to make this an industrial-scale production process,” says Arnab Basu, CEO and founder of Kromek.

At the company’s premises in Sedgefield, England, there are 170 petit fours in a room that Basu describes as “like a server farm.”

In these ovens, a special powder is heated, melted and then solidified, forming a single crystal structure.

The whole process takes weeks.

“Atom by atom, the crystals reorganize themselves (…) until they are completely aligned,” explains Basu.

CZT, a newly formed semiconductor, can detect tiny photon particles in x-rays and gamma rays with incredible precision, functioning as a highly specialized version of the light-sensitive silicon-based image sensor in your smartphone camera.

Every time a high-energy photon hits the CZT, like an X-ray, it mobilizes an electron and this electrical signal can be used to generate an image. Previous scanner technology used a two-step process, which was not as accurate.

“It’s digital,” says Basu.

“This is a single conversion step. It preserves all important information, such as the time and energy of the

He adds that CZT-based scanners are already being used to detect explosives at UK airports and to scan checked baggage at some US airports.

“We hope that CZT will be integrated into the carry-on segment in the coming years.”

The chosen material

But it is not always easy to obtain CZT.

Henric Krawczynski, a researcher at Washington University in St. Louis, US, has already used the material in space telescopes suspended in high-altitude balloons.

These detectors can capture X-rays emitted by both neutron stars and plasma around black holes.

Credit, Kromek

Professor Krawczynski needs very thin pieces of CZT, 0.8mm, for his telescopes because this helps reduce the amount of background radiation captured, resulting in a clearer signal.

“We would like to purchase 17 new detectors,” he says. “It’s really hard to find them that thin.”

Kromek could not help him because, according to Basu, the company is currently facing high demand.

“We support countless research organizations,” he adds. “It’s very difficult to do a hundred different things. Each research project requires a very specific type of detector structure.”

Many other scientists also use CZT.

In the UK, a major upgrade of the Diamond Light Source research center in Oxfordshire will improve its capabilities with the installation of CZT-based detectors.

The Diamond Light Source is a synchrotron that accelerates electrons around a giant ring to near the speed of light.

The magnets cause these electrons to lose energy as they pass through in the form of X-rays, directed towards light lines to, for example, analyze materials.

Some recent experiments have consisted of analyzing the impurities present in aluminum during its melting. Better understanding these impurities could help improve recycled metal forms.

With the Diamond Light Source upgrade, expected to be completed in 2030, the X-rays produced will be significantly brighter, meaning existing sensors will not be able to detect them properly.

“It doesn’t make sense to spend all this money improving these facilities if you can’t detect the light they produce,” says Matt Veale, head of the detector development group at the Science and Technology Facilities Council, one of the players in Diamond Light Source.

This is why, once again, CZT was the chosen material