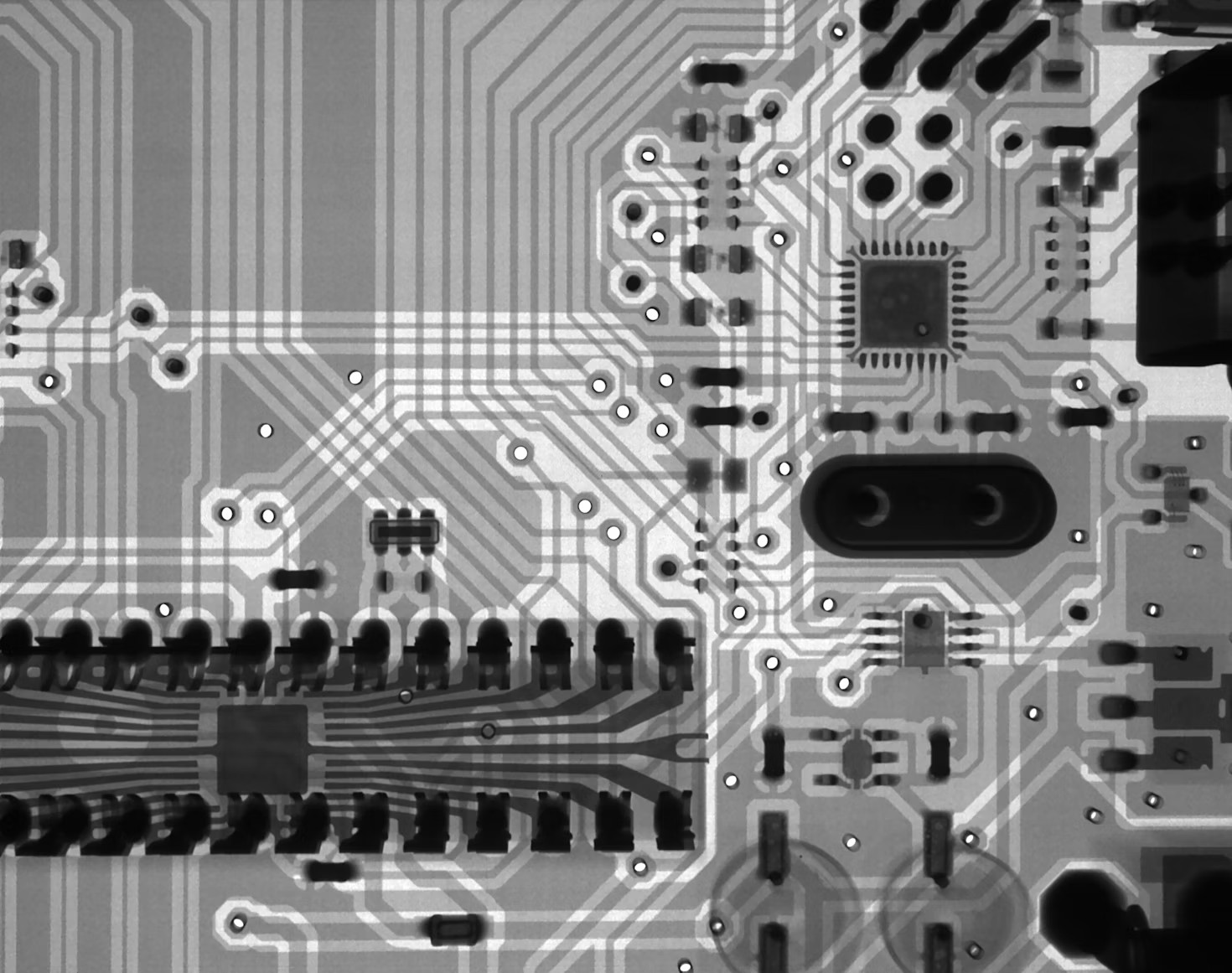

Japanese company Dai Nippon Printing (DNP) has developed technology that promises to reduce energy consumption by 90% in the manufacturing of advanced semiconductors. This discovery could significantly reduce the cost of producing artificial intelligence chips, according to “Nikkei Asia”.

Dai Nippon Printing plans to begin mass production in 2027 of a mold material that can be used to create modern 1.4-nanometer chips with Canon chipmaking equipment.

Currently, manufacturing these chips requires extreme ultraviolet (EUV) lithography equipment, produced exclusively by Dutch company ASML Holding. The lithography process, in which circuits are formed on silicon wafers, accounts for 30% to 50% of the total chip manufacturing cost.

The smaller the circuits, the more often ultraviolet light must be used, increasing power consumption. EUV lithography equipment costs hundreds of millions of dollars per unit, increasing already high production costs for chipmakers.

Japan’s Canon, a maker of semiconductor lithography machines, also has nanoprinting equipment for making chips, which creates circuits by essentially stamping them onto wafers.

The nanoprinting process was thought to be incompatible with chips 2 nanometers or smaller, but DNP developed a circuit mold that can be used with equipment to make 1.4 nanometer chips.

Canon began selling nanoprinting equipment, which consumes less power than EUV lithography devices, in 2023. The unit price is estimated to be several billion yen (1 billion yen is $6.4 million), much lower than the cost of EUV lithography.

As the mold comes into direct contact with the board to create the circuits, the presence of impurities can easily cause defects. Increasing speed is also a challenge. Some companies, such as memory chip maker Kioxia Holdings, have introduced nanoprinting equipment for testing, but none have adopted it into mass production lines.

The 1.4 nanometer chips will be used in artificial intelligence data centers and autonomous driving systems. South Korean companies Samsung Electronics and Taiwan Semiconductor Manufacturing Co. (TSMC) aim to launch mass production in 2027 and 2028, respectively.

Both are interested in nanoimprint lithography, but their factories were designed for photolithography equipment, which poses a major obstacle to evolving production methods. Nanoprinting equipment will need to be economically viable to achieve widespread adoption.

Canon and Nikon once dominated the global photolithography equipment market. But ASML won the race to miniaturization and now holds 90% of the market.

If the nanoprinting market grows in the future, it could create opportunities for materials manufacturers like DNP. Fujifilm Holdings announced plans to enter the market by producing materials applied to wafers during circuit formation.

In 2024, Canon sent its first nanoimprint lithography equipment to the Texas Institute for Electronics, a public-private organization that includes the state of Texas and semiconductor companies such as Intel.